00:00 - 00:00

2024.7.5

Recently, Xinhua News Agency reported on its overseas social media platforms (X, Facebook, YouTube) and the overseas edition of Xinhua Net that the main cable inspection robot "Climber" (CCRobot-M), developed by the Shenzhen Institute of Artificial Intelligence and Robotics, carried out intelligent inspection on the Cuntan Yangtze River Bridge in Chongqing.

"Climber" is a main cable appearance detection equipment based on the handrail rope in the attached facilities of the suspension bridge as the climbing carrier, and two groups of holding boots alternately open and close and creep forward. After many iterations, the performance of this version of the "Climber" has been greatly improved. The robot has the function of rail change, and the distance between the boot can be adjusted horizontally, which can better adapt to the environment of different suspension bridge cable system. Bionic peristaltic technology, the two groups of boots alternately open and close, and always have two groups of boots in the state of holding the armrest rope, from the crawling mechanism to ensure the safety of the robot does not fall; The modular design concept of the whole machine makes the assembly process more efficient and simplifies later maintenance and upgrading work.

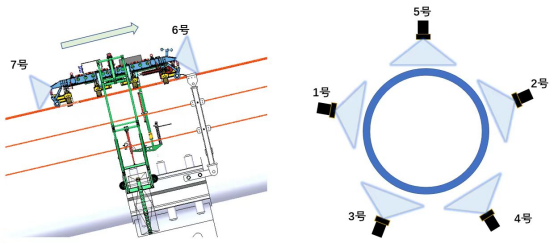

The vision sensor array carried by the robot is distributed in a ring surround, and the automatic pitch adjustment function is added. The detection camera is installed at the end of the support arm composed of lightweight composite materials, and the position can be automatically adjusted according to the diameter of the main cable, so as to obtain high-definition apparent images and realize the full coverage detection of the main cable.

Vision sensor ring surround

During the test, the "Climber" assisted in identifying loose bolts, missing bolts, pits and other defects, and successfully climbed the tower in the mid-span. The summit verified the excellent dynamic performance and long-distance climbing ability of the "Climber", and provided new equipment and new methods for the intelligent detection of the main cable of the suspension bridge.

Robots' do their jobs'

Protect bridge health

In addition to the "Climber" for main cable detection, AIRS Special Robot Center has also developed a robot CCRobot-C for cable detection. CCRobot-C has excellent speed, high load capacity and excellent obstacle crossing performance. It can be equipped with a variety of detection instruments, including vision and magnetic leakage, for multi-dimensional detection. It is suitable for cable and sling, and has functions such as autonomous operation and real-time wireless data return. The robot has been applied in Chongqing, Zhejiang, Hubei and other places.

As a member of the special robot center full bridge overhaul robot group, the two detection robots "each perform their duties" on the main cable and sling, escort the urban bridge safety, and help the construction of China's transportation power. This is also an important reflection of AIRS 'positive response to the "robot +" application action and focusing on typical application scenarios to carry out robot development.

The Climber

Led by Dr. Ding Ning, Executive vice president of Shenzhen Artificial Intelligence and Robotics Research Institute (AIRS) and vice president of Robotics and Intelligent Manufacturing Research Institute of the Chinese University of Hong Kong (Shenzhen), the Special Robot Center is oriented to the maintenance, maintenance and emergency response needs of urban infrastructure such as Bridges, tunnels, transmission lines and underground pipe networks. The autonomous maintenance robot system that can assist or replace operators to work in urgent, difficult, dangerous, heavy and other high-risk areas is developed, and is committed to promoting the sustainable development of people and cities.